Millermatic® 355 MIG/Pulsed Welder #907808

The Millermatic 355 is an easy-to-use machine designed to boost efficiency and productivity for manufacturing and fabrication users. Featuring a 7" color LCD screen, this all-in-one welder is equipped with Auto-Set™ Elite, an Electronic Parameter chart, and Trigger Program Select for seamless operation. The Millermatic 355 connects to any North American input power, making it highly versatile and adaptable to various work environments. Capable of welding up to 1/2” aluminum, stainless steel, and mild steel, it delivers power, precision, simplicity, and versatility. It can MIG and pulsed-MIG weld materials in thicknesses ranging from 22 gauge to 1/2 inch, with advanced features ensuring that welders of all skill levels can achieve productive and high-quality results. Whether operating on single-phase or three-phase AC input power, the Millermatic 355 is ready to work wherever you do.

What’s Included:

What’s Included:

- Power source with 9 ft. (2.7 m) industrial power cord

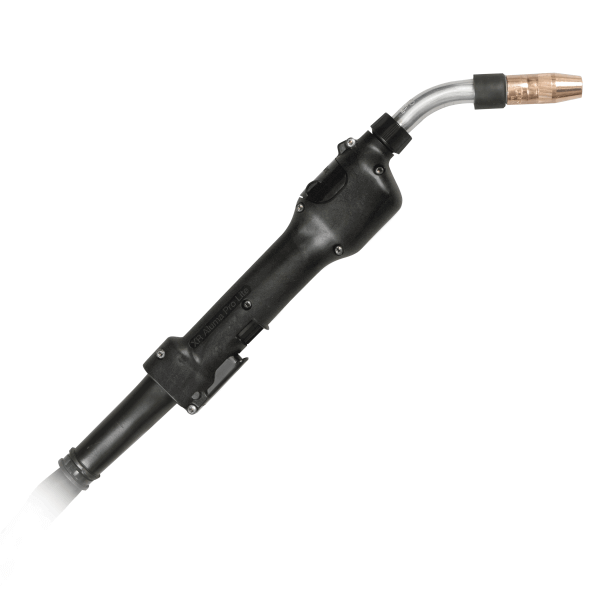

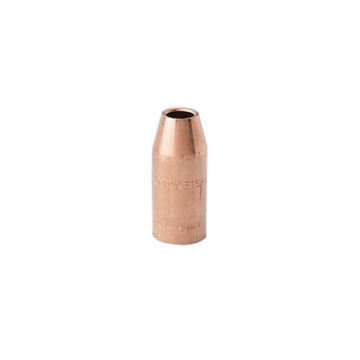

- 15 ft. (4.5 m) 300-amp Bernard BTB MIG gun with Bernard AccuLock S consumables for .035/.045 in. (0.9/1.2 mm) wire

- 10 ft. (3 m) work cable with clamp and 50 mm Dinse-style connector

- Flow gauge regulator and gas hose for argon or AR/CO2 mix

- .035/.045 in. (0.9/1.2 mm) reversible drive rolls

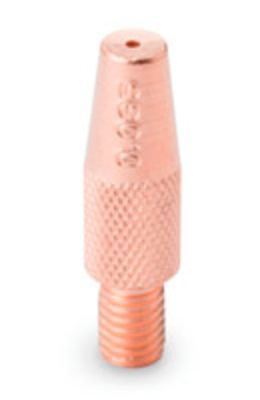

- Extra .035 and .045 in. (0.9 and 1.2 mm) contact tips

- Material Thickness Gauge

FEATURES OF THE MILLERMATIC 355:

- Easy-to-understand interface - 7-inch color LCD display ensures proper machine setup and parameter selection, reducing setup time and increasing weld time

- Pulsed MIG welding delivers higher quality - Lower heat input for less distortion on thin materials, less spatter minimizes post weld grinding and rework allowing more welding time. Perform welding applications that couldn’t be done in the past.

- Auto-Set™ Elite - offers predefined weld settings to increase ease of use and ensure that the job is done right for operators of all skill levels.

- Program mode allows easy save and recall of favorite weld settings. Deliver more productivity, consistent quality by welders of all skill levels by using prequalified weld settings. Minimize supervisor need to intervene.

- Trigger Program Select - Increases productivity by eliminating the need to go back to the machine to change weld settings. Simply tap gun trigger to select the program.

- Versatility - Capabilities include MIG, pulsed MIG and flux-cored welding.

- Bernard BTB Gun 300 A MIG gun with AccuLock™ S consumables - AccuLock liner loads from the front and locks at the front and back to insure proper alignment for flawless wire feed path. New rubber overmold and ball -and-socket handle design improves grip and reduces welder fatigue. New Industrial Bernard AccuLock™ S contact tips provide superior Spray and Pulsed MIG arc performance.

- Portability - Machine only weighs 99 lb. Weight is reduced by more than 40 percent compared to the Millermatic 350P.

- Optional EZ-Latch™ running gear - Operators no longer need to use lift truck to load machine and running gear into the truck. Latches secure machine to running gear. Simply loosen the latch retaining knob and rotate latches to disengage machine from running gear for easy portability

- Generator Compatible - The Millermatic 355 will be able to operate and provide full output when powered by generators with 19000 Watt (19K) output or higher. Limited output will occur when used with smaller generators.

- Input Voltage Selection Switch - Provides versatility to utilize any single- or three-phase North American power (208, 240, 460, 575 V). Location in the wire drive compartment provides the ability to manually switch input voltage. An error will display if wrong input selected.

Millermatic® 355 Applications:

- Commercial Truck and Trailer

- Construction / Fabrication

- Education / Training

- Fabrication

- Maintenance and Repair - In Plant

- Manufacturing

- Transportation

Try these accessories with your new Millermatic® 355:

+

Running Gear

View Product+

Spoolmatic 15A Welding Gun

View Product+

Spoolmate 200

View Product

Speedy, Free Shipping & No-Hassle Returns

Rapid fulfillment for items in stock - shipped the very same or following day direct from our distribution facilities spanning Wisconsin and Illinois. Leveraging UPS ground's swift services, your deliveries will arrive promptly. Require specialized shipping arrangements? Simply dial 1-844-682-0205, and our team will gladly accommodate any request, including utilizing your preferred carrier accounts. Purchase with confidence thanks to our hassle-free 14-day return policy on new, factory-sealed merchandise. Exceptional customer service is our hallmark, backed by industry-leading shipping and return practices. Elevate your ordering experience and capitalize on these advantages with your upcoming purchase!

Check out our wide selection of engine-driven welders/generators for sale.

This product replaces these legacy models:

Other versions of the Millermatic 355:

Miller Dynasty 280 DX Specifications: | |

|---|---|

| Brand | Miller |

| Model | Millermatic® 355 |

| SKU | 907808 |

| Processes | MIG (GMAW) Pulsed MIG (GMAW-P) Flux-cored (FCAW) |

| Input Power | 3- or 1-phase, 208/240/460/575 V, 50/60 Hz |

| Output | 3-phase: 310 A at 29.5 V, 60% duty cycle 1-phase, 460 or 575 V: 310 A at 29.5 V, 60% duty cycle 1-phase, 208 or 240 V: 310 A at 29.5 V, 60% duty cycle |

| Welding Mode | CV |

| Weldable Materials | Aluminum Specialty Metals Stainless Steel Steel |

| Portability | Running Gear / Cart (Optional) |

| Warranty | 3-Year Miller True Blue Warranty |

| Advanced Features | 7-inch color LCD display Auto-Set™ technology Pulsed MIG |

| Wire Diameter | Aluminum 0.035 in. - 0.047 in. Aluminum 0.9 mm. - 1.2 mm. Metal-Core 1.2 mm. - 1.3 mm. Metal-Core 0.045 in. - 0.052 in. Stainless 0.023 in. - 0.045 in. Stainless 0.6 mm. - 1.2 mm. Solid Steel 0.9 mm. - 1.2 mm. Solid Steel 0.035 in. - 0.045 in. Flux Cored 0.035 in. - 0.045 in. Flux Cored 0.9 mm. - 1.2 mm. Silicon Bronze 0.030 in. - 0.035 in. Silicon Bronze 0.8 mm - 0.9 mm. |

| Spool Size | 12 in. (305 mm) |

| Wire Feed Speed Control | 1.3 m/min - 20 m/min 50 IPM - 800 IPM |

Browse all Miller MIG welders

SHIPPING DIMENSIONS |

|

| Height: | 19.25 Inches |

| Width: | 19.00 Inches |

| Length: | 26.25 Inches |

| Weight: | 99 Lb(s) 0 Oz |

Accessories

Consumables

Manufacturer Reviews

Product Questions and Answers

How to Set Up Your Millermatic® 355

- Mount the Welder on Running Gear.

Secure the welder on the running gear by positioning the feet, rotating the latches, and tightening the thumb screws.

- Connect to Power Supply.

Adjust the input power selector switch to the appropriate voltage, close the cover, and turn on the power switch.

- Set Up Auto-Set Elite Feature.

Activate Auto-Set Elite and select wire type, gas type, wire diameter, and material thickness.

- Connect and Adjust Gas Cylinder.

Secure the gas cylinder, attach the regulator and hose, and adjust the flow rate to 20-30 cfh.

- Manual Mode and Parameter Fine-Tuning.

Switch to manual mode, adjust voltage and wire feed speed, and save settings to a program slot if desired.

MIG Gun

MIG Gun Multi Phase Input

Multi Phase Input Portable

Portable 3-Year Miller Warranty

3-Year Miller Warranty