Miller Spoolmate 200 Series #300497

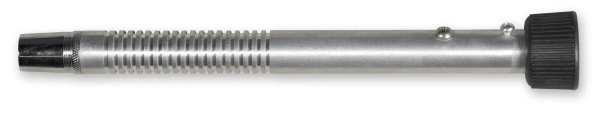

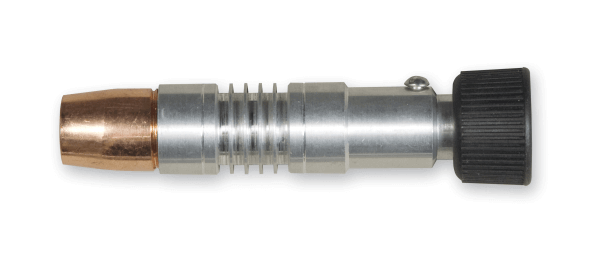

The Miller Spoolmate 200 is a light industrial spoolgun rated at 160 amps at 60% duty cycle. It's ideal for welding with .023 to .035 wires. A 20' direct-connect cable with heavy-duty strain relief is included for extended reach to your work. This cable connects this spoolgun to the Millermatic 212 Auto-Set, Millermatic 251 and Millermatic 252.

Included in this package:

- 20 ft cable

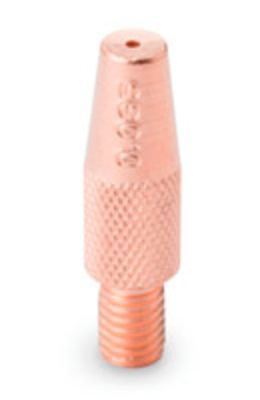

- Extra contact Tips

Overview of the Spoolmate 200:

Wire speed adjustment located on the gun handle allows the user to conveniently change wire speed directly from the spool gun. Saves time by eliminating the need to walk back to the welding machine to change the wire feed settings.

Easy access to drive assembly reduces service time by allowing easy access to drive rolls or performing routine maintenance without disassembly of gun.

Built-in gas valve eliminates the need to purge long gas lines.

Internally routed gas lines means the gas line won't get in the way of the work.

Hinged wire spool cover makes it easy to access wire compartment.

Pressure lever for easy loading and unloading of wire.

Adjustable drive roll tension for feeding different types of wire.

Easy to remove barrel options with several optional barrels allows welding in tight spaces and corners.

For the best prices on welding machine accessories, shop Welders Supply online.

Miller Spoolmate 200 Series Part #300497 Specs | |

|---|---|

| Industries & Interests |

|

| Amperage Rated Output |

|

| Cable Length |

|

| Head Angle |

|

| Torch Handle Type |

|

| Torches Type |

|

| Wire Size |

|

| Dimensions |

|

| Weight |

|

SHIPPING DIMENSIONS |

|

| Height: | 5.00 Inches |

| Width: | 16.00 Inches |

| Length: | 16.00 Inches |

| Weight: | 13 Lb(s) 0 Oz |

Accessories

Consumables

Product Questions and Answers

How to Turn on Shielding Gas:

-

Open Valve.

Open valve on cylinder just before welding.

-

Turn on Flow.

Turn on the gun trigger for weld output and also gas flow on and off.

-

Gas Preflow & Postflow.

For shielding gas preflow and postflow, lightly press the trigger before and after welding.

-

Close Valve.

Close valve on cylinder when finished welding.