453 MIG Welding Accessories Starting at $119.20

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 84 Dual Bench with Heavy Duty Wire Reel Stand #K5002-5

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 84 Dual Bench with Heavy Duty Wire Reel Stand #K5002-5

Lincoln Welding and Plasma Cutting Accessories

Activ8X® Pipe / Magnum® PRO Curve HDE 250 One-Pak® #K4968-2

Lincoln Welding and Plasma Cutting Accessories

Activ8X® Pipe / Magnum® PRO Curve HDE 250 One-Pak® #K4968-2

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 74 HT - Digital U/I, Heavy Duty Reel, Gouge Kit #K3883-14

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 74 HT - Digital U/I, Heavy Duty Reel, Gouge Kit #K3883-14

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 84 Dual Boom Feeder One-Pak® #K5002-11

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 84 Dual Boom Feeder One-Pak® #K5002-11

Lincoln Welding and Plasma Cutting Accessories

HELIX® SF70A-2 M85 Onboard Wire Feeder & Wire Manipulator Kit #K52245-2

Lincoln Welding and Plasma Cutting Accessories

HELIX® SF70A-2 M85 Onboard Wire Feeder & Wire Manipulator Kit #K52245-2

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 74 HT - Simple U/I, Hvy. Dty. Reel, Gouge Kit #K3883-13

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 74 HT - Simple U/I, Hvy. Dty. Reel, Gouge Kit #K3883-13

Lincoln Welding and Plasma Cutting Accessories

Activ8X® Pipe CE (Twist Mate / Dinse®) #K5240-1

Lincoln Welding and Plasma Cutting Accessories

Activ8X® Pipe CE (Twist Mate / Dinse®) #K5240-1

Lincoln Welding and Plasma Cutting Accessories

LN-23P Portable Field Wire Feeder #K316L-1

Lincoln Welding and Plasma Cutting Accessories

LN-23P Portable Field Wire Feeder #K316L-1

Lincoln Welding and Plasma Cutting Accessories

Activ8X™ / Magnum® PRO Curve 300 Wire Feeder One-Pak® #K3564-1

Lincoln Welding and Plasma Cutting Accessories

Activ8X™ / Magnum® PRO Curve 300 Wire Feeder One-Pak® #K3564-1

Lincoln Welding and Plasma Cutting Accessories

LF-74 Wire Feeder, Base Model #K2426-4

Lincoln Welding and Plasma Cutting Accessories

LF-74 Wire Feeder, Base Model #K2426-4

Lincoln Welding and Plasma Cutting Accessories

DLF-82 Base Model Wire Feeder #K5282-1

Lincoln Welding and Plasma Cutting Accessories

DLF-82 Base Model Wire Feeder #K5282-1

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 84 Single or Dual Control Box, No U/I #K5004-2

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 84 Single or Dual Control Box, No U/I #K5004-2

Lincoln Welding and Plasma Cutting Accessories

LF-74 Wire Feeder, Bench Model, Heavy Duty #K2426-5

Lincoln Welding and Plasma Cutting Accessories

LF-74 Wire Feeder, Bench Model, Heavy Duty #K2426-5

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 74 HT - Simple U/I, No Reel #K3883-1

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 74 HT - Simple U/I, No Reel #K3883-1

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 74 HT - Digital U/I, Std. Dty. Reel #K3883-6

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 74 HT - Digital U/I, Std. Dty. Reel #K3883-6

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 74 HT - Digital U/I, Gouge Kit #K3883-4

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 74 HT - Digital U/I, Gouge Kit #K3883-4

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 84 Single Bench with Contactor and Gouge Stud, No Wire Reel Stand #K5000-3

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 84 Single Bench with Contactor and Gouge Stud, No Wire Reel Stand #K5000-3

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 74 HT - Simple U/I, Std. Dty. Reel #K3883-5

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 74 HT - Simple U/I, Std. Dty. Reel #K3883-5

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 84 Dual Bench with Contactor, Heavy Duty Wire Reel Stand #K5002-2

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 84 Dual Bench with Contactor, Heavy Duty Wire Reel Stand #K5002-2

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 84 Single Bench with Heavy Duty Wire Reel Stand #K5000-2

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 84 Single Bench with Heavy Duty Wire Reel Stand #K5000-2

Lincoln Welding and Plasma Cutting Accessories

HELIX® SF70A-1 M85 Onboard Wire Feeder & Wire Manipulator Kit #K52245-1

Lincoln Welding and Plasma Cutting Accessories

HELIX® SF70A-1 M85 Onboard Wire Feeder & Wire Manipulator Kit #K52245-1

Lincoln Welding and Plasma Cutting Accessories

Activ8X™ CE (Twist Mate™/Dinse®) #K3519-2

Lincoln Welding and Plasma Cutting Accessories

Activ8X™ CE (Twist Mate™/Dinse®) #K3519-2

Lincoln Welding and Plasma Cutting Accessories

DLF-82 Bench Model, Wire Reel Stand #K5282-2

Lincoln Welding and Plasma Cutting Accessories

DLF-82 Bench Model, Wire Reel Stand #K5282-2

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 84 Single Drive Boom One-Pak® #K5000-11

Lincoln Welding and Plasma Cutting Accessories

Flex Feed® 84 Single Drive Boom One-Pak® #K5000-11

MIG Welding Accessories For Sale Online

MIG welding is a versatile and efficient welding process that requires not only skill but also the right accessories to ensure quality and precision. This comprehensive guide covers essential MIG welding accessories, their functions, and how to select the best ones for your needs.

Essential MIG Welding Accessories

MIG Welding Wire

MIG welding wire is a critical component that serves as the filler material. There are different types of wires, including:

- Solid Wire: Commonly used for welding thin materials, offering a clean and smooth finish.

- Flux-Cored Wire: Ideal for outdoor welding due to its resistance to wind and contaminants.

Choosing the Right Wire

Selecting the appropriate wire depends on the base material, welding position, and required strength. For example, ER70S-6 is popular for its versatility in welding various steel types.

MIG Welding Gun

The MIG welding gun is the tool through which the wire is fed and the arc is formed. Key features to consider include:

- Ergonomics: A comfortable grip reduces fatigue during prolonged use.

- Amperage Rating: Ensure the gun can handle the maximum amperage of your welder.

Gas Cylinders and Regulators

Shielding gas is crucial in MIG welding to protect the weld pool from atmospheric contamination. Common gases include:

- Argon: Used for welding non-ferrous metals.

- CO2: Economical choice for welding steel.

- Argon-CO2 Mix: Provides a balance of arc stability and weld penetration.

Nozzles and Contact Tips

Nozzles and contact tips are essential for directing the shielding gas and transferring the electrical current. Ensure they are regularly inspected and replaced to maintain optimal performance.

Advanced MIG Welding Accessories

Spool Guns

Spool guns are particularly useful for welding aluminum. They prevent wire feed issues by keeping the wire spool close to the gun, minimizing feeding problems associated with softer wires.

Push-Pull Systems

Push-pull systems are advanced wire feeding solutions that provide consistent wire delivery, even over long distances. This setup is beneficial for high-volume production environments.

Welding Curtains and Screens

Safety is paramount in welding. Welding curtains and screens protect bystanders from harmful UV rays and spatter. They also help contain sparks and prevent workplace accidents.

Welding Positioners and Clamps

To achieve precise and consistent welds, use welding positioners and clamps. These tools hold the workpiece in the desired position, reducing the need for manual adjustments and ensuring a stable welding environment.

Maintenance and Safety Accessories

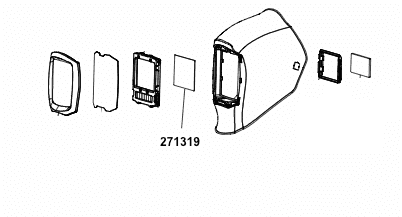

Protective Gear

Welders must wear appropriate protective gear to safeguard against burns, UV radiation, and fumes. Essential items include:

- Welding Helmet: Auto-darkening helmets provide convenience and protection.

- Gloves: Heavy-duty gloves protect against heat and spatter.

- Jackets and Aprons: Fire-resistant clothing shields the body from sparks and heat.

Cleaning Tools

Proper maintenance of your welding equipment extends its lifespan and ensures consistent performance. Cleaning tools such as wire brushes, chipping hammers, and nozzle dip help remove slag and spatter from the weld area.

Consumable Kits

Having a well-stocked consumable kit ensures you have replacement parts readily available. These kits typically include contact tips, nozzles, diffusers, and liners.