239 Hypertherm Plasma Cutter Consumable Parts Starting at $8.00

Hypertherm Accessories

FineCut SmartSYNC Mechanized Cartridge (30-45 A) #428926

159 purchased

Hypertherm Accessories

FineCut SmartSYNC Mechanized Cartridge (30-45 A) #428926

159 purchased

Hypertherm Accessories

Powermax45/45 XP Essential Handheld Kit #851510

556 purchased

Hypertherm Accessories

Powermax45/45 XP Essential Handheld Kit #851510

556 purchased

Hypertherm Accessories

Powermax 85/105 Nozzle (65-85 A) #220816 (5/pk) or #228760 (25/pk)

1138 purchased

Hypertherm Accessories

Powermax 85/105 Nozzle (65-85 A) #220816 (5/pk) or #228760 (25/pk)

1138 purchased

Hypertherm Accessories

Powermax 105 Essential Handheld Consumable Kit #851471

9 purchased

Hypertherm Accessories

Powermax 105 Essential Handheld Consumable Kit #851471

9 purchased

Powermax Plasma Cutters

Powermax45/45 XP Essential Mechanized Cutting Consumable Kit #851511

161 purchased

Powermax Plasma Cutters

Powermax45/45 XP Essential Mechanized Cutting Consumable Kit #851511

161 purchased

Hypertherm Accessories

Powermax 65/85/105 Nozzle (45-65 A) #220819 (5/pk) or #228759 (25/pk)

1258 purchased

Hypertherm Accessories

Powermax 65/85/105 Nozzle (45-65 A) #220819 (5/pk) or #228759 (25/pk)

1258 purchased

Hypertherm Accessories

FineCut Swirl Ring for Powermax 45/45XP/65/85/105 (30-45 A) #220947

478 purchased

Hypertherm Accessories

FineCut Swirl Ring for Powermax 45/45XP/65/85/105 (30-45 A) #220947

478 purchased

Hypertherm Accessories

HyAccess Cutting Nozzle/Shield (30-65 A) #420410

37 purchased

Hypertherm Accessories

HyAccess Cutting Nozzle/Shield (30-65 A) #420410

37 purchased

Hypertherm Accessories

Powermax45/45XP/65/85 FlushCut Starter Consumable Kit (45A) #428746

58 purchased

Hypertherm Accessories

Powermax45/45XP/65/85 FlushCut Starter Consumable Kit (45A) #428746

58 purchased

Hypertherm Accessories

Extended Gouging Nozzle/Shield (30-65 A) #420412

43 purchased

Hypertherm Accessories

Extended Gouging Nozzle/Shield (30-65 A) #420412

43 purchased

Hypertherm Accessories

Powermax105 Drag Cutting Shield (85-105 A) #220992 (1pk) or #228798 (10pk)

55 purchased

Hypertherm Accessories

Powermax105 Drag Cutting Shield (85-105 A) #220992 (1pk) or #228798 (10pk)

55 purchased

Hypertherm Accessories

Handheld FineCut Deflector Shield (30-45 A) #220931 - For Powermax45/45XP/65/85/105

254 purchased

Hypertherm Accessories

Handheld FineCut Deflector Shield (30-45 A) #220931 - For Powermax45/45XP/65/85/105

254 purchased

Hypertherm Plasma Cutter Consumables

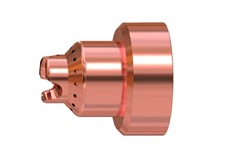

Hypertherm plasma cutting machines are well known by professionals and hobbyists for their portability, reliability, and ease of use. Even the most durable plasma cutting machines and torches will need consumable parts replaced after thorough use, however. Consumable parts are found in the cutting torch of your plasma machine and include swirl rings, electrodes, nozzles retaining caps and shield caps.

How long do Hypertherm plasma cutter consumables last?

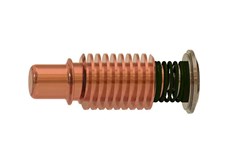

Because the nozzle and electrode are responsible for creating and directing the cutting arc, you can expect these parts to wear out the quickest. When the quality of your cuts begins to deteriorate, check the condition of your torch's nozzle. The hole in the tip gets larger with wear, reducing the precision of your cutting. Electrodes function by focusing the electric current from your torch, which can wear the hafnium within, creating a pit. Although this is normal, you'll want to replace your electrode when the pit gets around 1-1.6 mm deep.

Swirl rings, retaining caps and shield caps require less maintenance because they don't wear as quickly. It's a good idea to check these components regularly for cracks and imperfections and replace any damaged consumable parts. Replacing your Hypertherm consumables at the right time is essential for machine maintenance and for maintaining cut quality.