333 MIG Welding Machines Starting at $307.62

Shop our selection of MIG welders for sale from $307.62 to $69,834 from top manufacturers like Miller, Lincoln Electric, and ESAB. Choose from portable MIG welders, industrial MIG welders, and multi-process machines with MIG capability. Shop with Welders Supply to get the lowest online prices with free shipping on orders over $300.

ESAB

Warrior 300i MIG Multi-Process Welding Package #0558102559

ESAB

Warrior 300i MIG Multi-Process Welding Package #0558102559

Miller Welders

ArcReach Smart Feeder, Bernard PipeWorx 300 Amp Gun Pkg #951733

1 purchased

Miller Welders

ArcReach Smart Feeder, Bernard PipeWorx 300 Amp Gun Pkg #951733

1 purchased

What is a MIG Welder?

A MIG welder, or Metal Inert Gas welder, is a welding machine that uses an electric arc to melt and join metal parts. This process, known as Gas Metal Arc Welding (GMAW), feeds a continuous solid wire electrode through a welding gun into the weld pool, where it fuses with the base metals. A shielding gas, typically argon or a mix of argon and carbon dioxide, protects the weld from contamination. MIG welding is popular for its speed, versatility, and ease of use, making it suitable for both beginners and experienced welders working with materials like steel, aluminum, and stainless steel. Its straightforward setup allows for efficient welding with minimal cleanup.

How Much Does a MIG Welder Cost?

The price of MIG welders ranges from $307 to $69,834, depending on the brand, features, and capabilities. While there are budget MIG welders for sale under $500, lower-cost options often come with duty cycle limitations and may not be suitable for industrial applications like continuous production welding.

Popular MIG Welder Brands

Whether you're a professional welder or a DIY enthusiast, these trusted brands deliver proven performance for MIG welding applications:

- Miller - Industry leader known for superior arc performance and advanced technology like Auto-Set features

- Lincoln Electric - Long-standing reputation for reliable machines and excellent wire feeding systems

- Hobart - Quality welders that balance affordability with professional features

- ESAB - Innovative designs with digital controls and multi-process capabilities

- Blue Demon - Reliable entry-level and mid-range welders with solid performance for hobbyists and small shops

Types of MIG Welders

Different MIG welders support specific welding processes, each designed for particular materials and working conditions. Choose based on your typical welding environment and the materials you work with most often:

- GMAW (Gas Metal Arc Welding) - Traditional MIG process using solid wire and shielding gas. It produces clean welds with minimal spatter and is ideal for steel, stainless steel, and aluminum.

- FCAW (Flux-Cored Arc Welding) - Uses tubular wire filled with flux. Available with or without shielding gas, excellent for outdoor welding and rusty materials.

Most MIG welders can handle both processes with simple setup changes to polarity, drive rolls, and gas configuration.

GMAW vs FCAW Welding

|

GMAW |

FCAW |

|

|

Electrode Type |

Uses a solid wire electrode |

Uses a tubular electrode filled with flux |

|

Shielding Method |

External shielding gas, typically carbon dioxide and argon |

Self-shielded (FCAW-S) or gas-shielded (FCAW-G) |

|

Application |

Best suited for indoor welding or areas protected from wind |

Can be used outdoors and is more tolerant of windy conditions, especially FCAW-S |

|

Material Thickness |

Ideal for thinner materials, starting from 24-gauge up to 1/4 inch thick |

Better suited for thicker materials, typically 20-gauge and above, with some capable of welding up to 1/2 inch thick in a single pass |

|

Weld Appearance |

Produces cleaner welds with minimal slag and spatter |

Leaves slag that usually needs removal, and can create more spatter |

|

Skill Level |

Generally easier for beginners to learn and use |

Requires more skill to achieve optimal results, especially in setting up the wire feeder and power source |

|

Penetration |

Offers good penetration, but less than FCAW |

Provides deeper penetration, making it suitable for structural welding |

MIG Welding Consumables

Keep your MIG welder running at peak performance with regular replacement of these essential consumables:

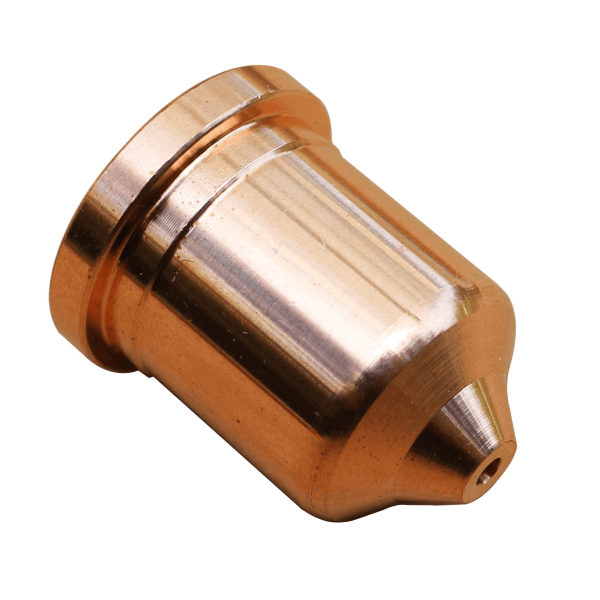

- Contact Tips - Transfers power to the welding wire. Replace when wire feed becomes erratic or tip shows signs of wear.

- Gas Nozzles - Directs shielding gas around the weld pool. Change when damaged or clogged with spatter.

- Gas Diffusers - Ensures even gas flow around the wire. Replace if gas coverage becomes uneven or when changing wire sizes.

- Liner - Guides wire from the spool to contact tip. Swap out when wire feeding becomes inconsistent or rough.

- Drive Rolls - Feeds wire at consistent speeds. Replace when worn or when switching wire types.

- MIG Wire - Available in various sizes and materials. Choose based on base metal and application requirements.

- Shielding Gas - Protects weld pool from contamination. Common types include 100% CO2 and Argon/CO2 mixes.

Regular inspection and replacement of consumables helps maintain weld quality and reduces downtime.

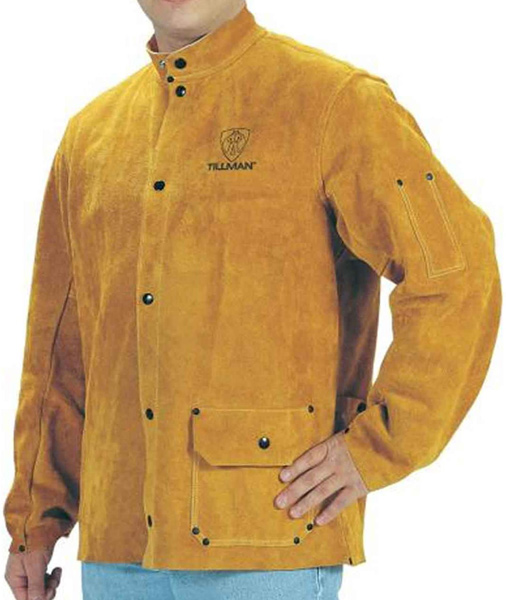

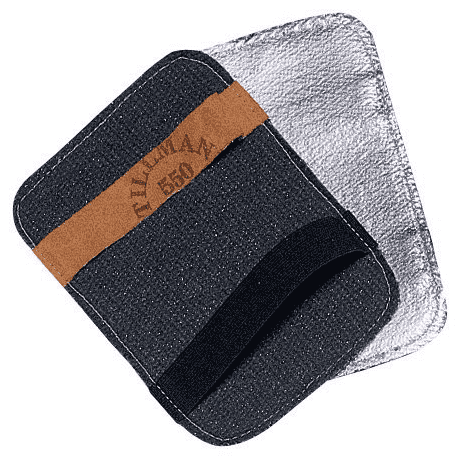

MIG Welding Accessories

MIG welder accessories enhance your welding capabilities, improve efficiency, and extend the life of your equipment. From precision control to mobility solutions, the right accessories can significantly upgrade your welding setup. Explore our range of welding guns, wire feeders, spool guns, and running gear to optimize your MIG welding experience.

MIG Welding Guns

MIG welding guns are the primary interface between you and your work. Choose from a variety of guns designed for comfort, durability, and precision.

MIG Wire Feeders

MIG wire feeders are crucial for consistent, smooth wire delivery during MIG welding. Our range of wire feeders offers options for various wire types and sizes, with features like adjustable speed control and quick-change drive rolls.

Spool Guns for MIG Welders

Spool guns are essential for welding soft wires like aluminum. These specialized guns house the wire spool close to the welding point, reducing feed issues and ensuring consistent wire delivery.

Running Gear for MIG Welders

Running gear adds mobility to your MIG welding setup, allowing you to easily move your equipment around the workshop or job site. Our selection includes sturdy carts and undercarriages designed to securely hold your welder, gas cylinder, and accessories.

Our more popular MIG welding machines include: