44 Replacement Welding Helmet Lenses Starting at $1.50

Maintain optimal visibility and safety with our extensive selection of replacement welding helmet lenses. Whether you need a simple passive shade 10 filter for a classic hood, a high-tech auto-darkening replacement cartridge for your Miller Digital Elite, or just a fresh clear cover lens to replace a pitted one, we have you covered. We stock genuine OEM lenses from Miller, Lincoln Electric, 3M Speedglas, and Optrel to ensure a perfect fit for your specific helmet model.

Miller Electric

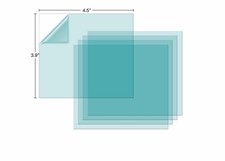

Digital Infinity Helmet Cover Lens, Outside #271320 (pack of 5)

4641 purchased

Miller Electric

Digital Infinity Helmet Cover Lens, Outside #271320 (pack of 5)

4641 purchased

Lincoln Electric

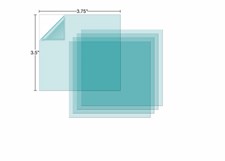

VIKING1740/1840 Series Outside Clear Cover Lens Pack #KP3043-1 (pack of 5)

508 purchased

Lincoln Electric

VIKING1740/1840 Series Outside Clear Cover Lens Pack #KP3043-1 (pack of 5)

508 purchased

Lincoln Electric

VIKING 3350 Series Inside Clear Cover Lens #KP3044-1 (pack of 5)

661 purchased

Lincoln Electric

VIKING 3350 Series Inside Clear Cover Lens #KP3044-1 (pack of 5)

661 purchased

Miller Electric

VS Series Outside Cover Lens #231411 (pack of 5)

750 purchased

Miller Electric

VS Series Outside Cover Lens #231411 (pack of 5)

750 purchased

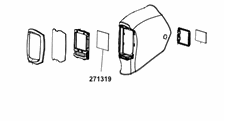

Miller Electric

Digital Infinity Helmet Cover Lens, Inside #271319 (pack of 5)

1408 purchased

Miller Electric

Digital Infinity Helmet Cover Lens, Inside #271319 (pack of 5)

1408 purchased

Lincoln Electric

VIKING™ 2450/3350 - Bulk Outside Cover Lenses #KP4628-1

2 purchased

Lincoln Electric

VIKING™ 2450/3350 - Bulk Outside Cover Lenses #KP4628-1

2 purchased

Lincoln Electric

VIKING™ 3350 ADV Inside Cover Lens - 5/PK #KP5244-1

7 purchased

Lincoln Electric

VIKING™ 3350 ADV Inside Cover Lens - 5/PK #KP5244-1

7 purchased

3M

Speedglas Welding Helmet Outside Protection Plate 9100 #06-0200-51

83 purchased

3M

Speedglas Welding Helmet Outside Protection Plate 9100 #06-0200-51

83 purchased

Miller Safety Equipment

T94(i) Helmet Cover Lens, Outside #265304 (pack of 5)

363 purchased

Miller Safety Equipment

T94(i) Helmet Cover Lens, Outside #265304 (pack of 5)

363 purchased

Miller Tables, Mounts, and Accessories

T94(i) Side Window Covers #260197

31 purchased

Miller Tables, Mounts, and Accessories

T94(i) Side Window Covers #260197

31 purchased

Lincoln Welding Helmets

Shade 14 Passive Welding Lens #KP1981-6

1 purchased

Lincoln Welding Helmets

Shade 14 Passive Welding Lens #KP1981-6

1 purchased

Types of Replacement Welding Lenses

A welding lens is the most critical component of your helmet. Over time, cover lenses get scratched, and auto-darkening batteries fail. Choosing the right replacement depends on your helmet shell and your welding process.

1. Cover Lenses (Inside & Outside)

These are the clear plastic shields that protect your expensive filter from spatter, smoke, and scratches. They are consumable items and should be replaced frequently.

- Outside Cover Lens: Takes the brunt of the heat and spatter. If your view is cloudy or pitted, replace this first.

- Inside Cover Lens: Protects the filter from sweat and dust inside the helmet.

- Tip: Always check your specific helmet model number (e.g., Miller Digital Elite, Lincoln Viking 3350) as cover lenses are not universal.

2. Auto-Darkening Filter (ADF) Cartridges

This is the electronic "brain" of the helmet. If your lens is no longer switching or has dead spots, you may need a replacement cartridge. High-end cartridges like the Miller T94i lens offer features like ClearLight™ technology for better color visibility.

3. Passive Filter Plates

For traditional "sugar scoop" helmets, these are the standard fixed-shade glass or polycarbonate plates (usually Shade 10 or 11). They are inexpensive, durable, and offer excellent optical clarity for Stick welding.

4. Cheater Lenses (Magnifying)

A Magnifying "Cheater" Lens inserts into your helmet to act like reading glasses. They are essential for TIG welders who need to see the fine details of a weld puddle without wearing glasses under the hood.

Frequently Asked Questions About Helmet Lenses

How do I know which cover lens fits my helmet?

Cover lenses are specific to the helmet shell series. For example, a Miller Digital Elite uses different lens dimensions than a Digital Infinity. Check your helmet's manual or the model number printed on the shell, then match it to the compatibility list in our product descriptions.

When should I replace my welding lens?

Cover Lenses: Replace them as soon as scratches, pits, or cloudiness obstruct your view. A dirty lens can cause eye strain and poor weld quality.

Auto-Darkening Filters: Replace if the lens flashes, fails to darken, or has cracks. If it is battery-powered, try changing the batteries first.

What shade lens do I need?

For general-purpose MIG and Stick welding at moderate amperages, a Shade 10 or 11 is standard. For high-amperage TIG or flux-core, you may need a Shade 12 or 13. Auto-darkening lenses allow you to adjust this range (typically 9-13) on the fly.