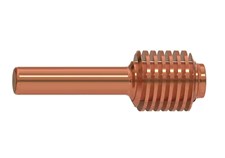

Hypertherm Powermax 30/Powermax45 Nozzle #220480

The Hypertherm Nozzle #220480 from Welder Supply precisely steers the stream of plasma for exact cutting. This plasma cutter nozzle is specially manufactured for the Hypertherm Powermax 30. When a plasma cutter nozzle and powered electrode hit metal, the spark fires the gas into plasma.

- The orifice in a torch cutting nozzle is designed to constrict the arc to a specific diameter without the arc touching the nozzle. The specially engineered nozzle directs the plasma arc to a specific diameter. The arc never actually touches the nozzle.

- The plasma gas generates a thin boundary layer of cool gas to maintain separation.

- During use, the arc may contact the cutting nozzle causing a double arc damaging the nozzle. Also, the nozzle could be gouged or the hole put out of round.

- Damaged nozzles should be replaced immediately. Quality is greatly reduced when the nozzles wear out.

- Gouges inside the nozzle are often caused by current being at too high a level or air flow too low. Piercing or cutting too fast can also cause nozzle damage.

Your Powermax 30 plasma cutter is an important investment, vital to your productivity. Keep it going strong with the Hypertherm Powermax 30 Nozzle #220480 from Welder Supply. These nozzles are a great value, offered in packs of five. Hypertherm Powermax plasma cutter consumable parts are available at Welders Supply to keep your plasma cutting machine functioning properly.

The Hypertherm Nozzle #220480 is compatible with:

- Hypertherm Powermax 30

- Hypertherm Powermax 45 (when used with 30 Amps)

Shop other Hypertherm products, Plasma Cutting Machines, Accessories, Welding Helmets, Helmet Accessories, Gloves, Jackets, Aprons, Caps, and Pants.

SHIPPING DIMENSIONS |

|

| Height: | 2.00 Inches |

| Width: | 4.00 Inches |

| Length: | 4.00 Inches |

| Weight: | 0 Lb(s) 0 Oz |

Consumables

Product Questions and Answers

Q - Do I need to replace anything else when I replace the nozzle?

A - It is recommended that when a nozzle wears out, the electrode is replaced, and when an electrode is replaced, the nozzle should also be replaced to keep cuts consistent and precise.

Q - When should I change the nozzle?

A - You should change your nozzle whenever you see notching, an orifice that isn't round, or rounded edges during your regular inspection.

Q - What does the nozzle do?

A - Nozzles focus the arc by funneling gas flow.