Miller Copilot™ Collaborative Welding System #951000110

Available in southern WI & northern IL only - Call 1-844-682-0205 to schedule a demo or get more information.

Introducing the Copilot™ with Auto Deltaweld™ 350, an innovative collaborative welding system designed for welders seeking advanced automation capabilities. This comprehensive package comes complete with all the components needed, featuring a 'Headless' power supply design that focuses the user interface on the intuitive Copilot™ teach pendant, simplifying operation over other solutions. Equipped with AccuGuide™ precision tuning and the IntelliSet™ settings assistant, you'll be programming and welding with unparalleled efficiency. Simplify your welding solution today with the powerful Copilot™ system. To explore its full potential, contact us for a demonstration at one of our locations.

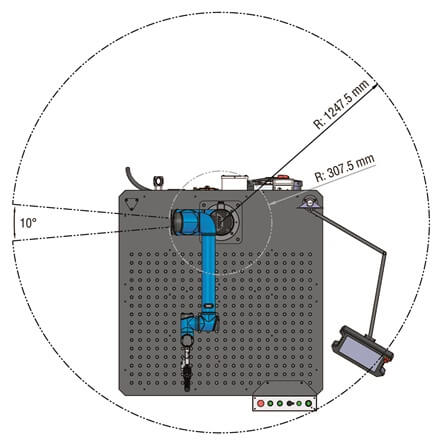

Cobot Work Envelope

Industrial Applications

Contract and OEM manufacturing of components for:

- Automotive & recreational vehicles

- Farm & construction machinery

- Marine

- Furniture

- & more

- Confab, worksite, and field fabrication

What's Included

- Auto Deltaweld 350

- Auto Deltaweld Basic fixed wire drive

- Welding Robot

- TOUGH GUN® CA3 robotic MIG gun

- Integrated Welding Table

- Strong Hand Tools kit

- All required interconnecting cables

Features of the Miller Copilot™

- Programming Puck - Reduce need to interact with pendant

- Tregaskiss® TOUGH GUN® CA3 robotic MIG gun - Accurate, reliable, and repeatable performance that maximizes production

- Teach Pendant Carriage - Convenient, hands-free viewing

- Andon Light Stack - Clear message communication to operator

- Portable Operator Pendant - Start/Stop programs in production

- Weld-Ready Tool Surface

- Debris Catch Trays

- Extra Storage

- Caster Wheels and Leveling Feet

Features of the Auto Deltaweld™ 350

- Easy to Integrate - New SubArc power sources integrate with standard Modbus connections

- Easy to Use - Programming and operation driven to cobot pendant for a single-point user interface

- Ethernet Receptacle - Allows webpage display and access for weld set up, troubleshooting, and power supply configuration.

- Fan-On-Demand™ - Cooling system operates only when needed, reducing noise, energy use and the amount of contaminants pulled through machine.

- ArcConnect - Next generation communication to improve weld performance and allow point-of-use controls to be located at the feeder.

- Wind Tunnel Technology - Internal air flow that protects electrical components and PC boards from dirt, dust, debris, greatly improving reliability.

- Accu-Pulse - Offers a more forgiving arc and compensates for variations in operator technique, providing a wider operating window.

See it in Action: Miller Copilot Demo

Accessories

- Ethernet cable - 9.8 ft or 32.8 ft

- Universal Connector for Analog Control

- Continuum Control/Motor Cable - 3 ft, 15 ft, 25 ft, 50 ft, 80 ft or 100 ft

Shop all welding cobots or browse Miller gear at the best prices online, from Welders Supply.

Other Versions of the Miller Copilot™:

| Copilot™ Collaborative Welding System Specs | |

|---|---|

| Processes |

|

| Industries Interests |

|

| Input Power |

|

| Standard Arc Welding Configuration |

|

| Payload Capacity |

|

SHIPPING DIMENSIONS |

|

| Height: | 84.00 Inches |

| Width: | 48.00 Inches |

| Length: | 52.00 Inches |

| Weight: | 1700 Lb(s) 0 Oz |

Collaborative Welding Robot

Collaborative Welding Robot Automated MIG Welding

Automated MIG Welding 120V Input (Copilot)

120V Input (Copilot) 208/230/460 V Input (Welder)

208/230/460 V Input (Welder) 1-Phase or 3-Phase (Welder)

1-Phase or 3-Phase (Welder) Miller 1-Year Warranty

Miller 1-Year Warranty