Industrial DC Multi-Process Welding Solution

The Lincoln Electric Idealarc® DC600 w/ VRD™ multi-process welder (K1288-28) is a rugged and versatile welding power source designed for heavy-duty shop applications. It features traditional SCR rectifier technology and VRD™ (Voltage Reduction Device™) for enhanced safety in challenging environments.

Highlights

-

Multi-Process Capability:

Supports Stick, TIG, MIG, Flux-Cored, Submerged Arc, and Gouging

-

100% Duty Cycle:

Rated for continuous operation at full output

-

VRD™ Technology:

Reduces open circuit voltage for added safety in high-risk environments

-

Full Range Output Control:

Easy operation and precise control

-

Analog Meters:

Standard ammeter and voltmeter for accurate monitoring

Key Features

- Rugged Construction: Built for demanding industrial environments

- Simple Controls: Easy to set up and operate

- Compact Design: Flat-top case with small footprint, stackable up to 3 high

- Environmental Protection: Windings and rectifiers protected against moisture and corrosion

Industries Served

- Heavy Fabrication

- Structural Fabrication

- Shipbuilding

- Construction

- Maintenance and Repair

Benefits of the Idealarc® DC600 w/ VRD™

- Enhanced Safety: VRD™ reduces shock risk in wet or humid conditions

- Versatility: Suitable for multiple welding processes and applications

- Durability: Designed for heavy-duty shop use

- Precise Control: Full range output voltage control for optimal welding performance

- Convenience: Auxiliary power for tools and accessories

This Idealarc® DC600 w/ VRD™ Multi-Process Welder offers a reliable, versatile, and safety-enhanced solution for industrial welding applications, combining traditional SCR technology with modern safety features for optimal performance in demanding environments.

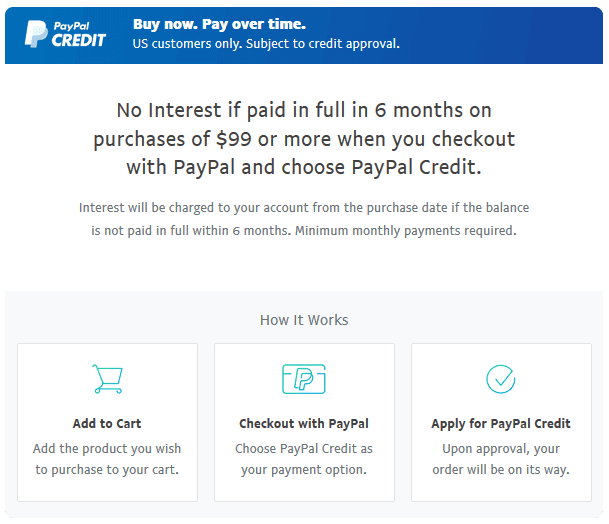

Fast, Free Shipping & Easy Returns

At Welders Supply, we prioritize fast, reliable shipping and hassle-free returns. If you’re not fully satisfied with your purchase, you can return it within 14 days for an exchange, credit or refund. Please ensure all products are returned freight paid, in their original packaging, with all materials, manuals and accessories included. A restocking fee of up to 25% may apply based on product condition. Certain restrictions apply to custom orders, PPE and demo items. Call our customer service team at 1-844-682-0205 for assistance.